Pultruded Fiberglass Grating

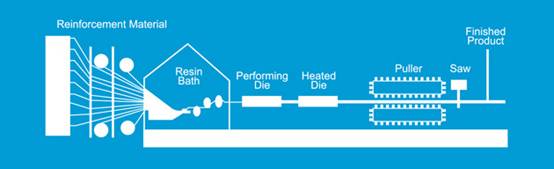

Pultruded Manufacturing Process

Pultruded Manufacturing Process and Selection

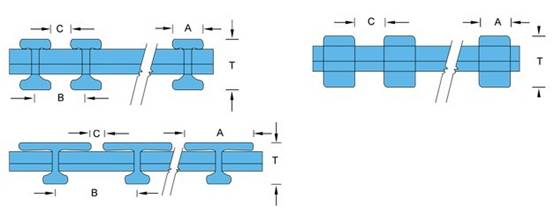

The pultrusion process utilized in the manufacturing of pultruded fiberglass grating and structural shapes is a continuous and automated process where continuous fiberglass rovings and mat are pulled through guides, a resin bath and pre-formers, then wrapped with a synthetic veil before being pulled through a heated die. The individual components of pultruded fiberglass grating – load bars and each piece of the two piece tie-bar are pultruded separately.

Load bars are then cut to specified lengths as they exit the machine. They are drilled at 6” or 12” centers for tie-bar insertion. Once the bars have been drilled they are spaced proportionately for the width of the panel at 3 ft, 4 ft or 5 ft. The two piece locking tie bar assemblies are then inserted creating multiple bonded intersections of load bars and tie bars, thus providing the security of both a mechanically locked and bonded connection. The final step in the process is to seal the cross bars and holes with corrosion resistant epoxy resin.

Pultruded fiberglass grating is uni-directional in strength and provides increased load capacity and very good levels of corrosion resistance. The components (bearing bars and cross bars) which are pulled by machine, provide a higher glass to resin ratio content (65% glass to 35% resin) which

gives it superior load capacity, yet reduces the corrosion resistance when compared to molded fiberglass grating.

Assembled from components, pultruded fiberglass grating can offer a wide variety of panel sizes and substantially reduce "scrap loss" not always possible from molded fiberglass grating panels. In addition, since the pultrusion process is automated, it produces a consistent, high quality finished product.

Advantages of Pultruded Fiberglass Grating:

• High Strength

• Exceptionally High Strength to Weight Ratio

• Lighter Weight

• Accomodates Higher Loads at Greater Spans

Type |

Height

inch

(mm)

|

Top edge width

(mm) |

Space between

(mm) |

Clearance width

(mm) |

Open area

(%) |

Estimated

Weight

Kg/㎡ |

I-4010 |

25 |

15 |

25 |

10 |

40 |

17.8 |

I-5010 |

25 |

15 |

30 |

15 |

50 |

15.1 |

I-6010A |

25 |

15 |

38 |

23 |

60 |

12.2 |

I-6010B |

25 |

8 |

19.8 |

11.8 |

60 |

13.7 |

I-4015 |

38 |

15 |

25 |

10 |

40 |

22 |

I-5015 |

38 |

15 |

30 |

15 |

50 |

19.1 |

I-6015 |

38 |

15 |

38 |

23 |

60 |

16.2 |

I-4012 |

30 |

15 |

25 |

10 |

40 |

19.1 |

I-5012 |

30 |

15 |

30 |

15 |

50 |

16.1 |

I-6012 |

30 |

15 |

38 |

23 |

60 |

13.1 |

I-40125 |

32 |

15 |

25 |

10 |

40 |

19.8 |

I-50125 |

32 |

15 |

30 |

15 |

50 |

17.4 |

I-60125 |

32 |

15 |

38 |

23 |

60 |

13.5 |

I-4020 |

50 |

15 |

25 |

10 |

40 |

28.5 |

I-5020 |

50 |

15 |

30 |

15 |

50 |

24.2 |

I-6020 |

50 |

15 |

38 |

23 |

60 |

20.1 |

T-1210 |

25 |

38 |

43.4 |

5.4 |

12 |

15.6 |

T-1810 |

25 |

38 |

50.8 |

9.5 |

18 |

13.8 |

T-2510 |

25 |

38 |

50.8 |

12.7 |

25 |

13.6 |

T-3310 |

25 |

41.3 |

61 |

19.7 |

33 |

11.2 |

T-3810 |

25 |

38 |

61 |

23 |

38 |

11.8 |

T-1215 |

38 |

38 |

43.3 |

5.2 |

12 |

19.6 |

T-2515 |

38 |

38 |

50.8 |

12.7 |

25 |

16.7 |

T-3815 |

38 |

38 |

61 |

23 |

38 |

14.2 |

T-3320 |

50 |

25.4 |

38.1 |

12.7 |

33 |

21.7 |

T-5020 |

50 |

25.4 |

50.8 |

25.4 |

50 |

17.2 |

HL-4020 |

50 |

15 |

10 |

10 |

40 |

62.8 |

HL-5020 |

50 |

15 |

15 |

15 |

50 |

52.2 |

HL-6020 |

50 |

15 |

23 |

23 |

60 |

43.5 |